Bolt-On Reversible Cutting Edges: A Farmer's Guide to Extended Lifespan and Cost Savings

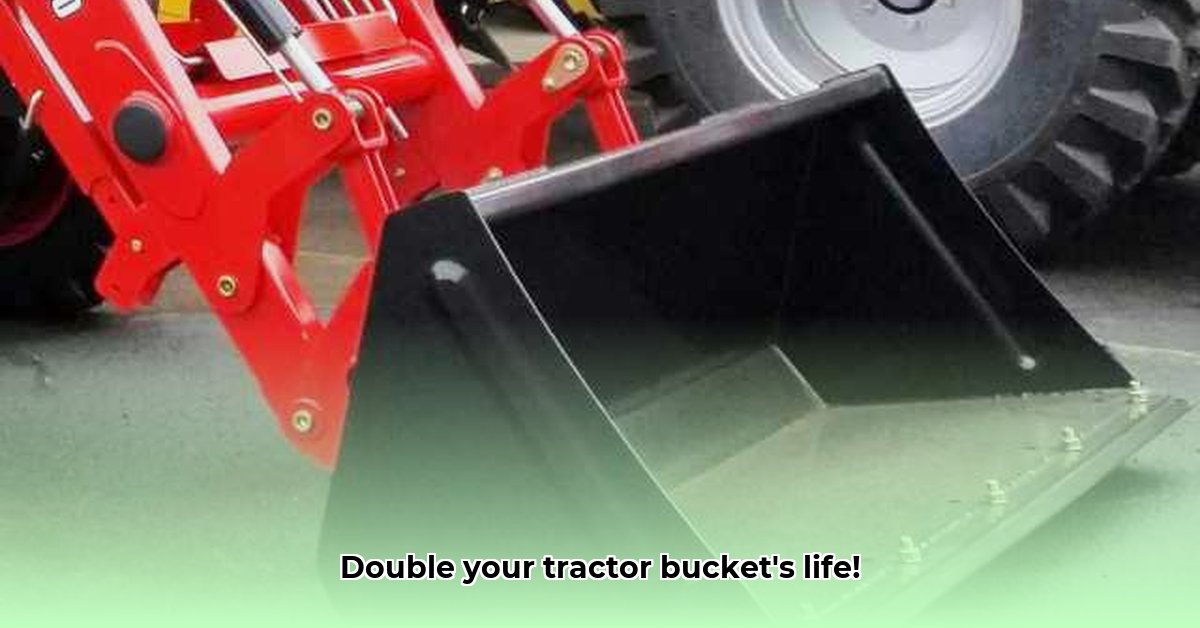

Tired of the constant expense and downtime associated with replacing worn-out tractor bucket blades? Bolt-on reversible cutting edges offer a practical, sustainable, and cost-effective solution. This comprehensive guide will walk you through everything you need to know—from understanding the technology to maximizing its lifespan and minimizing your environmental impact. Ready to double your bucket's life and significantly reduce your operational costs? Let's get started. For additional information on protecting your investment, check out this resource: bucket protection.

What are Bolt-On Reversible Cutting Edges?

Imagine a tough, replaceable "shell" for your bucket blade. Instead of replacing the entire blade when it wears, you simply replace this far more affordable, high-carbon steel edge. When one side wears out, you flip it over! It's like getting two blades for the price of one, significantly extending the life of your bucket. This simple innovation translates to substantial long-term savings and increased efficiency.

The Undeniable Benefits: Why Choose Reversible Cutting Edges?

The advantages extend beyond simple cost savings. Let's explore the key benefits:

Extended Lifespan: Reversible cutting edges can double or even triple the lifespan of your bucket blade compared to traditional blades, leading to significantly fewer replacements. Isn't that efficiency you can actually see?

Cost Savings: While the initial investment may be slightly higher, the cumulative savings from reduced replacements far outweigh the initial cost. This translates to a significant return on investment over time. Did you know that farmers who have switched report saving an average of 60% on blade replacement costs over three years?

Reduced Downtime: Less time spent on repairs means more time spent working the land—a critical factor impacting overall productivity and profitability. It's time well-spent that directly affects your bottom line, wouldn't you agree?

Environmental Responsibility: Reducing the number of blades sent to landfills is a significant step towards environmentally sustainable farming practices. This contributes to a smaller carbon footprint and reflects responsible stewardship of the environment.

Choosing the Right Reversible Cutting Edges: A Critical Decision

Selecting the appropriate cutting edges depends on several critical factors:

Steel Hardness: Look for high Rockwell hardness (Rc) ratings. A higher Rc number indicates a tougher, more durable edge capable of withstanding harsh conditions. The higher the Rc, the longer your blade will last.

Soil Conditions: Hard, rocky soils require harder cutting edges than those used in softer, more pliable soil types. Consider your typical soil conditions when selecting a suitable hardness level.

Bucket Compatibility: Ensure compatibility with your tractor bucket's dimensions and mounting system. Improper fitting can lead to performance issues and safety hazards. Double-check measurements before purchasing.

Brand Reputation: Invest in a reputable brand with a proven track record of quality and durability. Look for warranties that demonstrate confidence in their product's longevity. A good warranty is an indication of a manufacturer's confidence in their product’s quality.

Step-by-Step Installation Guide: A Simple Process

Installing your new cutting edges is typically straightforward, but safety is paramount.

Step 1: Preparation: Secure your tractor on level ground, engage the parking brake, and wear safety glasses and gloves.

Step 2: Removing the Old Edge: Use the appropriate tools (usually a wrench or impact wrench) to carefully remove the bolts holding the old edge.

Step 3: Attaching the New Edge: Align the new edge with the bucket blade, ensuring proper seating.

Step 4: Secure Fastening: Tighten the bolts evenly, avoid over-tightening. Consult your product's instructions for torque specifications.

Step 5: Final Inspection: Thoroughly inspect the installation for loose bolts or misalignments before operation.

Maintenance and Care: Maximizing Lifespan

Regular maintenance is vital for extending the life of your cutting edges:

- Regular Inspections: Check for wear, damage, or loose bolts. Address issues promptly.

- Cleaning: Clean the edges after each use to remove dirt and debris.

- Lubrication: Periodically lubricate bolts to prevent corrosion.

Recycling and Disposal: Sustainable Practices

Even reversible blades eventually need replacing. Explore recycling options at your local scrap metal yards or through manufacturer programs for responsible disposal.

Conclusion: A Sustainable Investment

Investing in reversible cutting edges is a decision that benefits your bottom line and the environment. They offer a sustainable, cost-effective solution to maintaining your equipment and maximizing its lifespan. Contact your local equipment supplier or search online for reputable brands to get started today.

Resources

- [Example Supplier Website 1] (Replace with actual link)

- [Example Supplier Website 2] (Replace with actual link)

- [Example Agricultural Organization Website] (Replace with actual link)